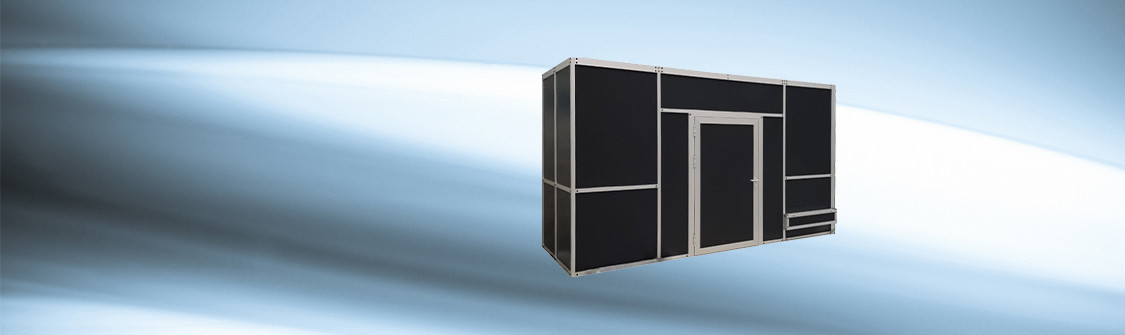

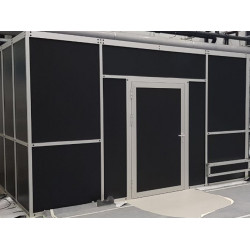

STC-Laserschutzkabine

Laser Safety Cabins for industrial and research applications

The laser safety ecabins are designed in a way, that for applications with class 4 lasers, the enviroment is properly protected and fullfills the class 1 conditions according to EN 60825-1 and OStrV.