SEI-FerrulePro-SPR-2

Lab and production measurement technology

Due to rapid changes in technology, new tasks for laboratory, production, and development applications are created on a daily basis. Laser 2000 offers a wide variety of test solutions to meet these challenges. Thanks to modular system solutions, expansions and changes can be made in a timely manner, thereby securing investments for the future. Laser 2000 offers microscopes for inspecting connector cleanliness as well as interferometers, RL/IL test solutions, polarization controllers and analyzers, optical switches, and more.

SEI-FerrulePro-SPR-1

Automatic Desktop Cleaner SPR-1

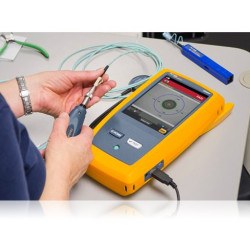

FLK-FI-7000

CertiFiber Pro Optical Loss Test Set

GPC-OCA-1000

Optical Component Analyzer

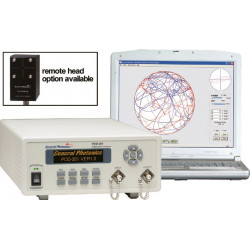

GPC-POD-201

Polarimeter - PolaDetect™

GPC-PCD-104

Polarization Scrambler - PolaMix™

GPC-MPC-201

Multifunction polarization controller

The multifunction polarization controller MPC-201 has four operating modes for complete control of the polarization.

The PolaMight (MPC-202) is an advanced Multifunction Polarization Controller specially designed to meet the requirements of coherent receiver performance tests.

GPC-POS-20x

Polarisations-Stabilisator PolaStay

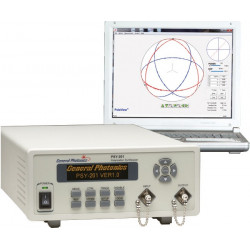

GPC-PSY-201

Polarization Synthesizer/Analyzer - PolaFlex™

GPC-ERM-202

Polarization Extinction Ratio Meter

The ERM-202 is a dual channel polarization extinction ratio (PER) meter specifically designed to simultaneously measure the PER and power ratio of a device with two polarization maintaining (PM) outputs, such as a Y-branch fiber gyro IOC, PM coupler (PMC), or polarization beam splitter (PBS), as well as evaluate the performance (output DOP) of depolarizers.

Popular Products

DAT-WinCamD-LCM

Laser Beam Profiler WinCamD-LCM

This laser beam profiler features a CMOS sensor that guarantees frame rates of up to 60 Hz with high dynamics and is suitable for large beam diameters up to 11 mm.

DAT-WinCamD-IRBB

2-16 micron Laser Beam Analyzer

The beam analysis camera WinCamD-IR-BB with integrated microbolometer array enables analyzes on long-wave lasers in the range of 2 μm to 16 μm.

DAT-WinCamD-QD-1550

Laser Beam Profiler WinCamD-QD-1550

DataRay's ILM system is used for beam profile monitoring of high power lasers consisting of an attenuator for high powers, an imaging lens system and a camera system. The measurement of very small laser beams with diameters of less than micrometers is possible despite often high laser powers.