OSE-HBCH

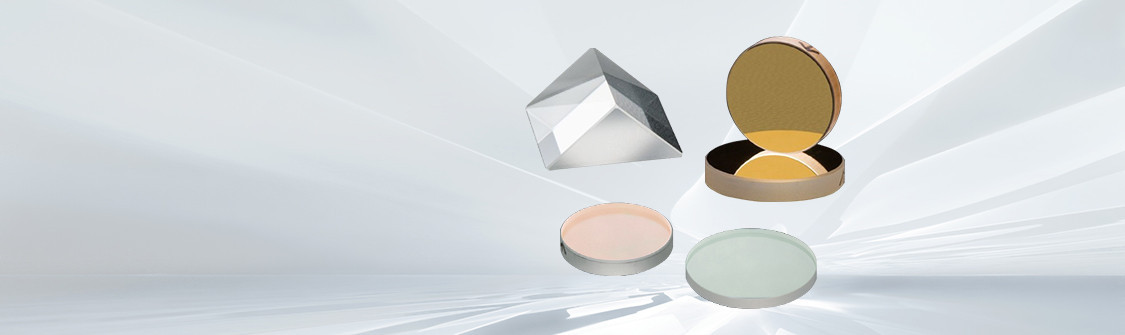

Optics and Optical Coatings

Optical coating consists of a combination of thin layers. These produce interfering effects that are used to improve the transmission or reflection characteristics of a system. The behavior of an optical coating depends on the number of lambda/4 layers, the thickness of the individual layers, and the differences between the refractive indexes of the individual layers. The most common coatings for precision optics are antireflection coatings (AR), highly reflective coatings (HR), beam splitter coatings, and filter coatings.

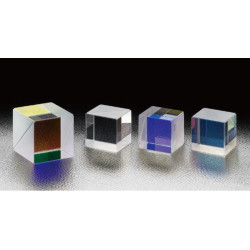

OSE-CSCH

Chromium Cube Half Mirrors

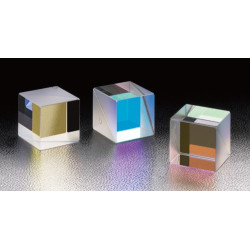

OSE-CSMH

Dielectric Cube Half Mirrors

OSE-PSMH-LL

Laser Line Plate Half Mirrors

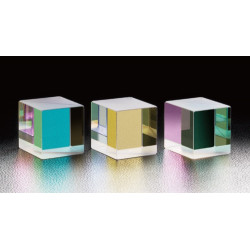

OSE-PSMH

Broadband Dielectric Half Mirrors

OSE-MPSMH

Thin Plate Beamsplitter

OSE-PSCH

Chromium Plate Half Mirrors

OSE-CSM33

Dielectric Cube Beamsplitters, 1:2

OSE-CSM25

Dielectric Cube Beamsplitters, 1:3

Popular Products

DAT-WinCamD-LCM

Laser Beam Profiler WinCamD-LCM

This laser beam profiler features a CMOS sensor that guarantees frame rates of up to 60 Hz with high dynamics and is suitable for large beam diameters up to 11 mm.

DAT-WinCamD-IRBB

2-16 micron Laser Beam Analyzer

The beam analysis camera WinCamD-IR-BB with integrated microbolometer array enables analyzes on long-wave lasers in the range of 2 μm to 16 μm.

DAT-WinCamD-QD-1550

Laser Beam Profiler WinCamD-QD-1550

DataRay's ILM system is used for beam profile monitoring of high power lasers consisting of an attenuator for high powers, an imaging lens system and a camera system. The measurement of very small laser beams with diameters of less than micrometers is possible despite often high laser powers.

DAT-M2DU

M2 Option for WinCamD

A main feature of the WinCamD is the optional M2 Stage. Thus, it can be easily extended to a complete M2 measurement system.