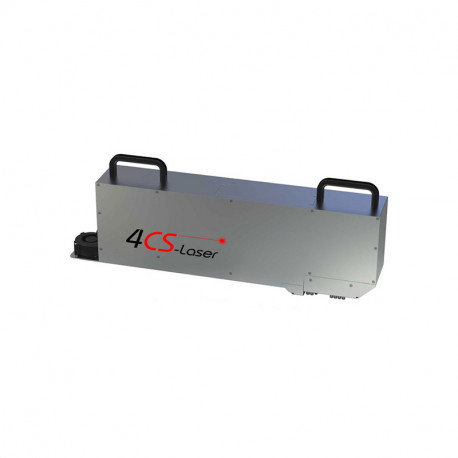

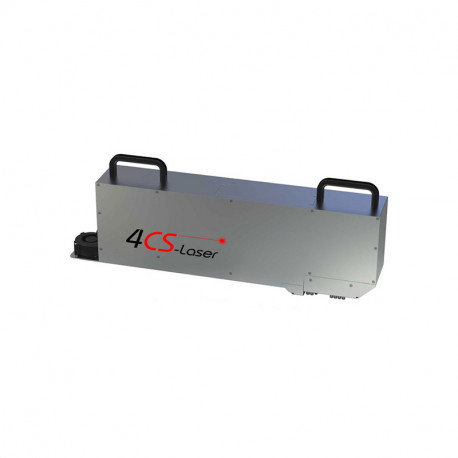

Laser Trim Unit

Reference number: 4CS-LasertrimmerUnit

Reference number: 4CS-LasertrimmerUnit

Need more info?

Contact our expert.

Solutions Team

Phone: +49 8153 405-11

Description

Laser unit systems developed by 4CS-Laser are designed for laser processing of micromechanics and microelectronics for research as well as for industrial production. Using pulsed laser sources, sophisticated optical components and a clear HMI software, laser trimming of thick- and thin film capacitors or resistors to a desired value is achieved very easily. Also labelling of substrates with simple numbers or even abstract patterns like e.g. a company logo, can be done straightforwardly.

Compact, modular construction:

Many technical systems struggle with the same problems:

« Short- and long-term stability».

Influences such as thermal drifts in electronic parts and components, mechanical materials with different geometries and unequal coefficients of thermal expansion are one of the reasons for stability issues. In part, insufficient product properties depend on influencing factors of different components. These effects can be compensated or corrected, however, if determination factors are known.

We at 4CS-Laser are aware of all these effects thanks to years of experience. Before designing our own laser systems, we identified the typical shortcomings, resolved them and developed a stable system through various innovations.

An innovative adjustable optical system allows to adjust the laser beam very precisely to the focal height.

Using several temperature sensors and a precise laser power measurement, temperature drifts can be detected and corrected. Power drift effects are common to any kind of laser sources and can not be avoided. In our system, laser power is monitored in-situ during production and is steadily adjusted.

Thanks to innovative ideas, a sophisticated laser system could be developed, which puts an end to all the typical shortcomings of standard systems.

Advantages of innovations:

Easy interchangeability