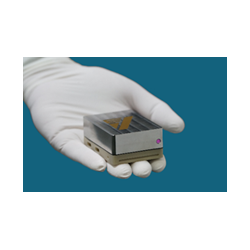

JDSU Solid-State Pulsed laser

Reference number: JDP-DPSS-Pulsed-Q-Series

The JDSU Q Series lasers are Q-switched diode-pumped UV and green lasers which are used for high-pulse-energy processing of materials such as ceramics, high-repetition-rate processing of materials such as sapphire or silicon.