3-D Inspection & laser Applications

In contrast to the 2D measurement technique, the 3D measurement technique also records information on the object shape in addition to the contrast. For an optimal result, the illumination in this case should be as uniform as possible in shape and intensity. High-quality line lasers meet precisely these decisive criteria and are therefore ideally suited to the popular triangulation measurement technique.

Wood processing industry

Wood processing industry

Wood is a limited raw material whose demand is not decreasing despite the ever-increasing prices. For this reason, the best possible utilization is of particular interest. In order to avoid unnecessary waste, the early detection of defects, the classification of wood and the consideration of fiber orientations play a decisive role in the modern wood industry.

In addition to 3D measurement of surfaces and edges with line lasers, systems with point lasers are also used here. The shape of the laser scatter on the surface can be used to make a statement about the fiber orientation, which is a factor in determining both the thickness and density of the material as well as where it is used.

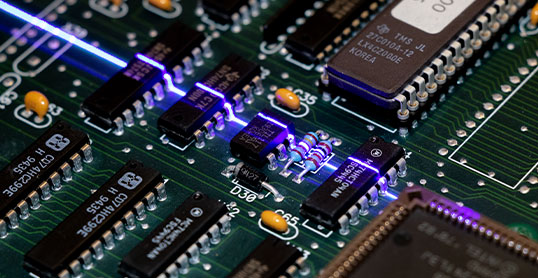

Electronics manufacturing

Hardly any everyday product can still do without electronics. The electronics industry is therefore one of the fastest growing and most innovative markets - with great competition. To remain competitive, not only the production quantity but also the scrap or the quantity of goods to be reworked is a key criterion. Many checks that used to be done by humans are nowadays replaced by an automated and intelligent process.

In order to highlight all these relevant features, optimal lighting is important, because insufficiently collected information means subsequent computational effort. Investing sufficient time in choosing the right lighting is therefore worthwhile. On the one hand, this saves computing power/time and thus increases cost efficiency in particular. On the other hand, once information has been lost, it cannot be recovered even with the best computer technology, which can set the work process back considerably.

In addition to lighting, there are other factors to consider when it comes to maintaining competitiveness. Powell lens technology, for example, can be used to achieve uniformly thick laser lines with a homogeneous intensity distribution. Also worth mentioning is the telecentric laser, where light propagation is parallel. Edge beams that would otherwise have to travel a longer distance toward the object thus also produce equal line thicknesses on the object, making this technology suitable for particularly demanding tasks.

Rail inspection

The demands placed on rail transport are increasing. Greater transport loads and higher speeds are pushing both trains and rails to their limits. Since in many countries freight and passenger traffic share the same routes, constant inspection is essential.

If the first defects and/or material fatigue are detected and repaired at an early stage, a prolonged disruption or, in the worst case, an accident will not even occur. Lasers, with their high power and good beam shaping properties, are particularly suitable here for performing condition analysis even at normal cruising speeds.

Compact, pulsed systems also allow complete measurement systems to be placed under almost any train. Additional measurement runs are thus no longer necessary and the remaining traffic remains virtually undisturbed.

These preventive measurements not only collect important data that lead to the development of ever better tracks, but also extend the useful life of many rails that would otherwise be replaced unnecessarily..

Back to the Application Machine Vision