DAT-WinCamD-LCM

Laser Beam Profiler WinCamD-LCM

This laser beam profiler features a CMOS sensor that guarantees frame rates of up to 60 Hz with high dynamics and is suitable for large beam diameters up to 11 mm.

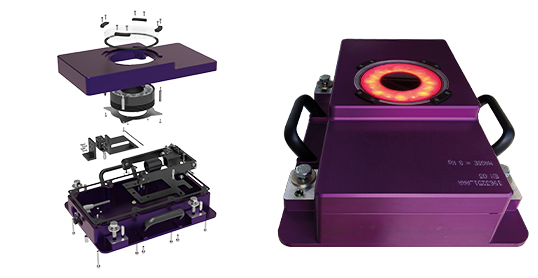

The Ariane Group entrusted us with the development of a vision system for aligning the boosters of the Ariane 6 launcher on their pallet. The goal was to guide the operator during descent and position them precisely on the pallet.

By placing two vision systems at 90° to each other on the pallet and two sights on the booster, the operator positions a 165-ton element with an accuracy of 0.1 mm. For this, we developed the mechanical interfaces, the optoelectronic system and the visualization software interface used in the operating area thanks to a customized PC embedded in a flight case.

By placing two vision systems at 90° to each other on the pallet and two sights on the booster, the operator positions a 165-ton element with an accuracy of 0.1 mm. For this, we developed the mechanical interfaces, the optoelectronic system and the visualization software interface used in the operating area thanks to a customized PC embedded in a flight case.

The required accuracy (0.1 mm) and the large depth of field were the main challenges. In addition, the required documentation and mechanical drawings had to be very detailed, and comply with the very high quality assurance measures and rules set by the customer. The mechanical specifications also had to not exceed the available volume to accommodate the light, camera and lens.

By using a high-resolution camera and a strong light, we were able to achieve great accuracy and visualize the target of the booster from its highest position to its final position on the booster. By applying agile methods and adapting our solution to the customer feedback, we developed the ideal software tool for this project.

DAT-WinCamD-LCM

This laser beam profiler features a CMOS sensor that guarantees frame rates of up to 60 Hz with high dynamics and is suitable for large beam diameters up to 11 mm.

DAT-WinCamD-IRBB

The beam analysis camera WinCamD-IR-BB with integrated microbolometer array enables analyzes on long-wave lasers in the range of 2 μm to 16 μm.

DAT-WinCamD-QD-1550

DataRay's ILM system is used for beam profile monitoring of high power lasers consisting of an attenuator for high powers, an imaging lens system and a camera system. The measurement of very small laser beams with diameters of less than micrometers is possible despite often high laser powers.

DAT-M2DU

A main feature of the WinCamD is the optional M2 Stage. Thus, it can be easily extended to a complete M2 measurement system.